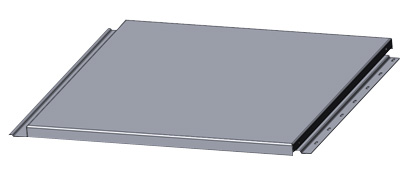

Coiled metal decoiler - RS-5

Feed rate, m/min – up to 30

Operating mode - automatic, manual, reverse

Installed power, kW - 5.5 max

Load capacity, kg - max 5000

Dimensions (LxWxH), mm –1355x1000x1600 max

Range of shaft segments opening, mm - 480…610

Shaft segment spreading drive - Manual screw drive

Weight, kg – 1200 max