+7(495) 640 21 99

+7(495) 640 22 07

+7(495) 640 21 99

+7(495) 640 22 07

In modern industries, there is often a need for the production of custom section of profiles.

BORA offers equipment for the production of custom profiles. The lines, depending on the number of profile types, can be executed in various versions

When ordering equipment for the production of one standard size, we offer a stationary rolling mill without additional adjustments and readjustments.

For the production of two or more types of profiles, we consider the cassette-type rolling line to be the most optimal choice. If there are minor changes in the geometry of the profiles, it is possible to manufacture a line with internal tooling changes.

Custom profiles can be produced with various options for technological holes (punches).

|

|

|

Various kinds of "ragging" can be performed on the profile shelves, for example, a company logo, or a measuring scale, etc.

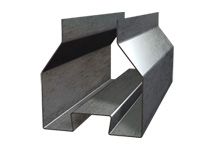

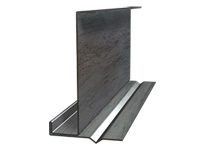

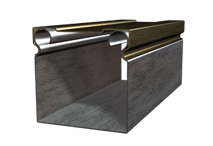

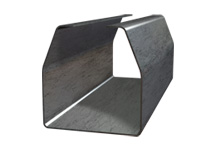

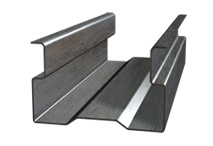

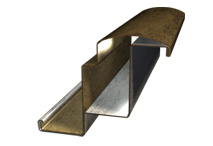

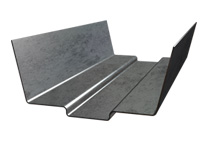

The cross section of such profiles can be very diverse.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. Tooling design. The design is carried out on the basis of the customer's technical specifications (drawings, sketches indicating the properties of the metal) using modern production automation technologies.

2. Manufacturing tooling on high-performance CNC turning equipment.

3. Bedding of the manufactured tool.

4. Pilot run of the profile production.