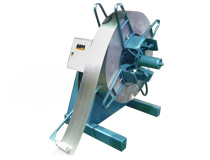

Cantilevered decoiler RS-1.5

Cantilevered decoiler RS-1.5

Type - (driven, cantilevered)

Weight - 300 kg

Load capacity - 1.5 t

Decoiler drive power - 2.2 kW

Decoiler drive type - Asynchronous, frequency-controlled by Vesper inverter

Coil inner diameter - 450-600 mm

Decoiler blades spreading mode - Manual by the screw drive

Max. coil width - 450 mm

External diameter of the coil processed - 1500 mm

Decoil speed synchronization - By slack loop, via control bar

Emergency sensor for disconnecting the line when the loop is pulled - Limit switch

Reverse mode - provided

Number of decoiler trunk blades - 4 pcs

Dimensions - 1200x800x1450 mm

NON-DRIVEN CATCHING TABLE (3-12 r.m.)

NON-DRIVEN CATCHING TABLE (3-12 r.m.)