+7(495) 640 21 99

+7(495) 640 22 07

+7(495) 640 21 99

+7(495) 640 22 07

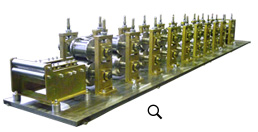

The rolling mill is designed for the production of profiles with a wall thickness of 0.4 - 2.5 mm. The design of the mill is distinguished by a reinforced housing and a powerful distributed drive.

The distribution of torque on the stands is carried out through gearboxes and quick couplings, which are installed on each stand.

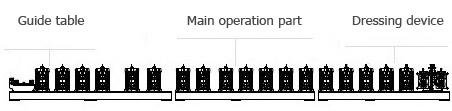

Replaceable cassettes are a plate with several shaping stands located on it, allowing for quick changeover of the rolling mill by replacing cassettes. The composition of interchangeable cassettes includes threading tables and dressing devices. To change over the mill, it is required to change one set of profiling cassettes for another and change the block of knives on the cutting guillotine.

No adjustments are made inside the cassettes, thereby saving the changeover time and the metal that would be required for the changeover.

* For the most complete satisfaction of the wishes of customers, one of the options for the execution of profiling replaceable cassettes also provides for internal readjustment, with a change of roll equipment on profiling stands.

Replaceable shaping section

Possible line options

|

Depending on the range, the thickness of the metal being processed and the complexity of the profiles produced, the type of housing and the drive power are selected.

Depending on the maximum number of shaping stands, the drive housings are divided into several models.

THE LINEUP:

THE LINEUP:«URM-8» - the maximum number of stands - 8 pcs.

«URM-10» - the maximum number of stands - 10 pcs.

«URM-12» - the maximum number of stands - 12 pcs.

«URM-18» - the maximum number of stands - 18 pcs.

«URM-24» - the maximum number of stands - 24 pcs.

The versatility of this equipment lies in the fact that it can be structurally included in a line built according to a modular circuit and adapted to perform various tasks based on standard elements.

- Decoiler

- Dressing roller machine

- Feeding device

- Punching device

- Marking machine (ink, impact)

- Perforating rotary die.

- Cutting device

- Flying-shears

|