Z- CHANNEL PRODUCTION LINE

METAL USED:

Cold-rolled galvanized steel in coils.

Steel grades – 08PS/KhP (08F/ 1008/ DC01) (GOST R 52146-2003).

- Band thickness range, mm – 0,9-1,2

- Original band width, mm - 83

- Productivity, m/min - 20

| 1.1 Cantilever decoiler RS-1,5M - Load capacity, t – 1,5 - Band width, mm - 450 max. - Number of blades, pcs - 4 - Paw spreading range, mm - 450-600 - Drive power, kW - 2,2 Decoiler blade spreader drive is manual. Operating mode - automatic by the control rod |

|

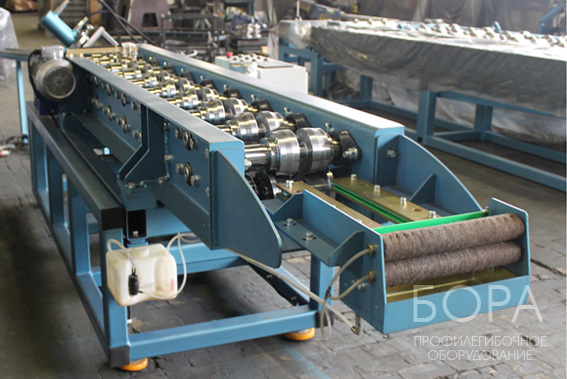

1.2 12-stand rollforming mill |

| 1.3 Electromechanical guillotine with a set of profile blades |

| 1.4 Catching table 6 running meters long |

| 1.5 ACS with 7" touch panel |

Power, kW - 4