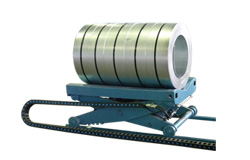

Automatic driven cantilever decoiler - "RG-10-1500" (10 t LC) with hydraulic spreading arms drive and a device for pressing the band with a drive roll

Automatic driven cantilever decoiler - "RG-10-1500" (10 t LC) with hydraulic spreading arms drive and a device for pressing the band with a drive roll

Type - Cantilever with attachable safety support

Weight - 2430 kg

Load capacity - 10 000 kg

The decoiler blades spreading mode - "wedge"

The decoiler blades spreading tool drive - hydraulic "Duplomatic"

Spreading stroke limit - 500-610 mm

Decoiler drive 4MTs2S – asynchronous frequency-controlled inverter "Vesper"

Decoiler drive power - 7.5 kW with electric brake

Metal decoiling speed - up to 40 m/min

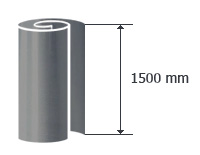

Width of coil processed - up to 1520 mm

Coil inner diameter - 500-600 mm

The outer diameter of the coil - 1450 mm

Operating mode - automatic

Loop tracking - extension rod

Emergency sensor for disconnecting the line when the loop is pulled - limit switch

Overall dimensions (LxBxH) - 2300x1160x1300 mm

Possibility of reverse rotation (in the opposite direction) - provided

The number of blades of the decoiler trunk - 4 pcs.