SPECIFICATIONS:

SPECIFICATIONS:

Adjustment of the thickness of the original metal from 0.42 to 0.6 mm

Productivity - 25 m / min

Installed line power - 6 kW

Line dimensions laterally 9 m x 1.5 m

Number of service personnel - 1 person

+7(495) 640 21 99

+7(495) 640 22 07

SPECIFICATIONS:

SPECIFICATIONS:

Adjustment of the thickness of the original metal from 0.42 to 0.6 mm

Productivity - 25 m / min

Installed line power - 6 kW

Line dimensions laterally 9 m x 1.5 m

Number of service personnel - 1 person

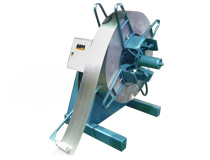

Cantilevered decoiler RS-1.5

Cantilevered decoiler RS-1.5

Type - (driven, cantilevered)

Weight - 300 kg

Load capacity - 1.5 t

Decoiler drive power - 2.2 kW

Decoiler drive type - Asynchronous, frequency-controlled by Vesper inverter

Coil inner diameter - 450-600 mm

Decoiler blades spreading mode - Manual by the screw drive

Max. coil width - 450 mm

External diameter of the coil processed - 1500 mm

Decoil speed synchronization - By slack loop, via control bar

Emergency sensor for disconnecting the line when the loop is pulled - Limit switch

Reverse mode - provided

Number of decoiler trunk blades - 4 pcs

Dimensions - 1200x800x1450 mm

ACS (Automated control system)

ACS (Automated control system)

Operating modes

Manual - Operation of drives by pressing buttons

Semi-automatic - Operation of the guillotine drive by pressing a button, the rest in automatic mode

Automatic - Operation of drives according to the controller program

Material change mode - Line and cut-off stop for waste-free material change

Emergency mode - Line stop without resetting the program in case of failure or malfunction of the decoiler, stacker, guillotine

Finished panels cut-off accuracy - ±1-2 mm

Number of programmable positions (quantity by length) - 16

Control panel - Touch 7", multifunctional "Delta Electronics"

The " EAVE TRIM " flashing production line - on request