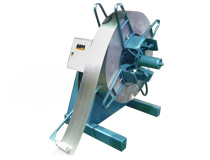

Roll decoiler - RS-1,5

Roll decoiler - RS-1,5

Type - Driven, Cantilevered

Weight - 300 kg

Load capacity – 1.5 t

Decoiler drive power - 2.2 kW

Decoiler drive type - Asynchronous, frequency-controlled by Vesper inverter

Coil inner diameter - 450-600 mm

The decoiler blades spreading mode - Manual by the screw drive

Max width of the coil - 450 mm

Coil outer diameter - 1500 mm

Decoiling speed synchronization - By slack loop, via control bar

Emergency sensor for disconnecting the line when the loop is pulled - Limit switch

Possibility of reverse rotation - provided

The number of the decoiler trunk blades – 4 pcs

Overall dimensions - 1200x800x1450 mm

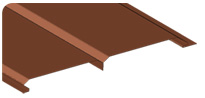

Profile bending mill "Double Ecobeam"

Profile bending mill "Double Ecobeam"